Small Radius Heavy Duty Omni-Grid®

Features

Specifications

Options

Downloads

Features

SMALL RADIUS HEAVY DUTY OMNI-GRID® 360

SMALL RADIUS HEAVY DUTY OMNI-GRID® 360

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

BELTS THAT RUN SMOOTHER, STRONGER, LONGER

SPIRAL

LOTENSION

HYGENIC

THE HIGHEST TENSION RATED BELT IN THE SMALL RADIUS BELT MARKET

THE HIGHEST TENSION RATED BELT IN THE SMALL RADIUS BELT MARKET

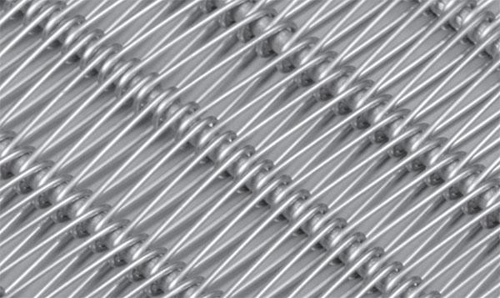

The Small Radius Heavy-Duty Omni-Grid® 360 Weld is made up of strong rods and links, designed for durability. The center row of heavy-duty links creates two lanes for products, with sturdy, heavy-duty collapsing links on the inside edge and heavy-duty collapsing bar links on the outside edge. Every link offers a secure single weld.

With 360-degree welds, the heavy-duty links provide extra strength, making the belt ideal for spiral, low-tension, and turn-curve applications. The Small Radius Heavy-Duty Omni-Grid 360 Weld is available with a turn ratio ranging from 1.0 to 1.59 times the belt width.

Small Radius Heavy Duty Omni-Grid® 360 Weld Link

Competitor Link

ENGINEERED FOR HIGHER STANDARDS

ENGINEERED FOR HIGHER STANDARDS

Small Radius Heavy-Duty Omni-Grid conveyor belts can negotiate a much tighter turn than regular Omni-Grid belts. In general, the inside radius can be equal to 1.1 times the belt width, making Small Radius Heavy-Duty Omni-Grid ideal for use in applications where heavy product loads or floor space is limited. Small Radius Heavy-Duty Omni-Grid can turn either left or right, pivoting about a center link.

Small Radius Heavy-Duty Omni-Grid conveyor belts can negotiate a much tighter turn than regular Omni-Grid belts. In general, the inside radius can be equal to 1.1 times the belt width, making Small Radius Heavy-Duty Omni-Grid ideal for use in applications where heavy product loads or floor space is limited. Small Radius Heavy-Duty Omni-Grid can turn either left or right, pivoting about a center link.

RESISTANT

TO STICKING

IN FREEZER APPLICATIONS

PROVEN RELIABILITY

PROVEN RELIABILITY

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

All belts are tested and rated for 100,000 cycles versus competitor ratings of only 50,000 cycles. The 1-inch pitch and 1½-inch pitch Omni-Grid® 360 Weld belts are also offered with integral guard-edges with a smooth rounded finish for applications where product retention is a concern. Available in .75-inch, 1-inch, and 1.5-inch pitch, the Omni-Grid 360 Weld belts are the strongest and longest running grid style belts on the market today

STANDARD FEATURES

STANDARD FEATURES

Omni-Tough Mesh Overlay

21/2 times stronger than conventional overlays and is resistant to product sticking in freezer applications.

Pigtail Spirals

Reduces wire breakage.

OPTIONAL FEATURES

OPTIONAL FEATURES

Integral Guard Edges

Now with smooth, rounded edge finish. Durable and easier to clean than modular guard edges. Available for 1 inch and 1.5 inch pitch belts.

Special Mesh Spirals

A cost effective solution for adding land dividers

DIRECTION

Specifications

Technical Specifications

| Technical Specifications | Units | SROG360-075 |

|---|---|---|

| Turn Ratio | 1.1-2.0 | |

| Pitch | in. [mm] | 0.75 [19.0] |

| Available Widths: Curve/Spiral | in. [mm] | 12-48 (305-1219) |

| Available Widths: Straight Run | in. [mm] | 12-48 (305-1219) |

| Link Height | in. [mm] | 0.44 [11.1] |

| Rod Diameter/Material | in. [mm] | 0.192 (4.9) Metal |

| Conveying Surface | in. [mm] | Width -1.50 [-38.1] |

| Allowable Tension (Curve/Spiral) | lb. [kg] | 150 [68] at 100,000 cycles (when configured for maximum strength) |

| Allowable Tension (Straight Run) | lb. [kg] | 300 [136] at 100,000 cycles (when configured for maximum strength) |

| Turn Direction | Uni-directional (left or right-must specify direction) | |

| Mode of Turning | Inside edge collapses in turn | |

| Method of Drive | Sprockets driven on links |

Belt Calculator

No Results

Base Belt Weight

Belt Pitch

Turn Ratio

Belt Strength

Min Filler Roll Diameter

Conveying Surface

Inside Conveying Surface

Outside Conveying Surface

Mesh Opening Size

Open Area Surface

Open Area Thru

Need more detailed information?

Need more detailed information?

Need more detailed information?

Options

Product Options

Omni-Tough Mesh Overlay

- Stainless steel, spring wire, spiral overlay available in 16 and 17 wire gauges.

- 2-1/2 times stronger and more damage-resistant than conventional wire overlays.

- Provides a flatter surface than standard overlays.

- More resistant to product sticking in freezer application.

Designation

B/U X - Y - Z

- B/U = Balanced or Unilateral Weave

- X = Number of Loops/Foot of Width

- Y = Number of Spirals/Foot of Length

- Z = Wire Gauge of Overlay

Examples:

B30-16-16

U42-16-17

Need more detailed information?

Need more detailed information?

Need more detailed information?

Downloads

Downloads

Installation, Assembly & Maintenance Instructions

Conveyor System Review Form